Caustic soda recovery system

During mercerizing process of cotton woven,knit or yarn, in textile processing industry,large quantities of caustic soda are utilized. every 1 kg of cotton requires 240 gms 100% NaOH to be mercerized. 80% of this washed out during stabilizing leaving 5% concentration weak lye. this is drained to sewer or sent effluent treatment plant to be neuteralized before drain. rafae engineering caustic recovery system economically concentrates the filtered weak lye thus recycling caustic soda and hot distilled water to the mercerizing. the system is lined up with mercerizing machine by installing the weak lye concentration control system which assures optimized operation of caustic recovery system.

Technology

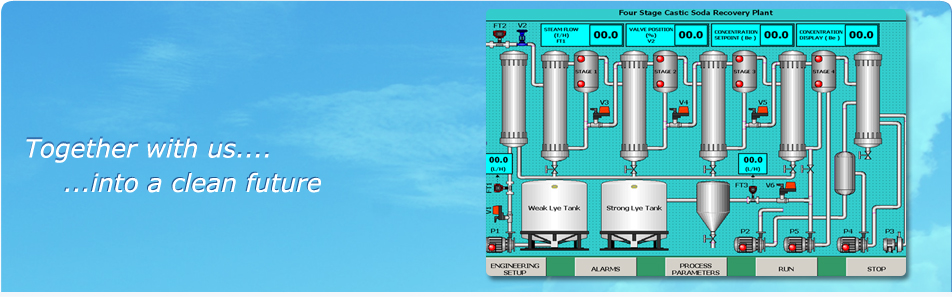

RAFAE Engineering design multistage evaporation plant as per customers requirements of hot water ,heat source available. the diffirence is in the consumption of cooling water produced. the 2 stage plant needs more steam and produce more cooling water than 4 stage plant, but the investment cost are lower. the main issue is the cooling water. if you are able to use the cooling water later in the process, the 2 stage plant is better choice, if you have already enough warm water and this is often the case by new machines, so you should consider 3 or 4 stage plant.

The caustic recovery plant is a multistage evaporating process with natural circulation and with steam saving, i.e. only first stage is heated up with steam . the condensate is sent back to boiler. the weak lye is preheated with waste vapours of the last stage. boiling takes place in the tubes and vapor liqure mixers enters the separator where efficient separation takes place and vapores enter the shell of next stage. there is pressure and temperature gradient from the first to last stage produced by condenser and vacuum pump due to which pumpless transfer of liqure is possible in successive stages. the vapors from the last stage are condensed in surface condeser. the distillate is contineously fed to mercerizing through weak lye concentration control system. condenser cooling water is fed to bioler house or production house.

The recovered caustic upon reaching desired concentration setpoint is automatcally discharged to a lye purification system

Characteristics of caustic soda recovery system

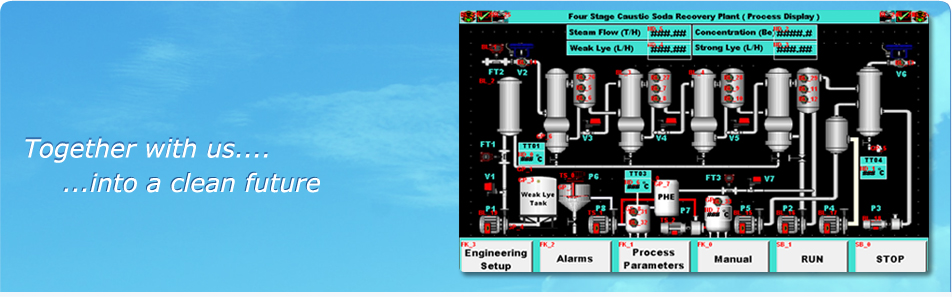

The control includes fully automatically controled processing steps by a process control system with touch screen on the plant site and operator work station in a office room connected by lan-network. data logging is provided for cost benefit analysis.